- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NCW

Main Features

●Modular design improves expandability as well as maintainability and reduces equipment complexity and cost

●Suitable for MIG wire, no laser wire required

●The Shifter can handle workpieces of different shapes and sizes, and through multi-axis rotation and tilting, it realizes the need for all-round welding and machining of various complex workpieces.

●The automatic wire feed system ensures consistency of the weld material during the welding process, thus significantly improving weld quality and consistency.

| Power | Material | Stainless steel | Carbon steel | Galvanized sheet | Aluminum |

| 1500W | Max. welding thickness | 3mm | 3mm | 3mm | 3mm |

| 2000W | 5mm | 5mm | 5mm | 4mm | |

| 3000W | 7mm | 7mm | 7mm | 5mm | |

| 100% penetration with one-sided welding | |||||

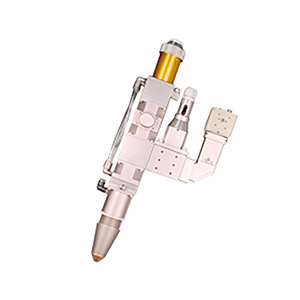

Welding head/torch

Dual wobble welding method

Auto wire feeding machine

Digitally controlled wire feeding, 4-wheel wire pulling + wire guide hose + wire guide nozzle

Multi-language operating system

More than 10 languages, Arabic, English, German, French, Japanese, Polish, Spanish, Portuguese, Russian, Thai, Korean, etc.

High-load robots

6 axes - high load capacity - high stability - maintenance free

Welding shifter

Laser control, double-tap trigger, safety circuit

Integrated control cabinets

Integrated lasers, wire feeding systems, laser control systems, chillers

Parameter

| Model | NCW1500 | NCW2000 | NCW3000 | ||

| Laser Wavelength | 1080nm | ||||

| Laser Power(W) | 1500W | 2000W | 3000W | ||

| Optical Fiber Length(m) | 10(Default) | 20(Default) | |||

| Welding Head Type | Double wobble (Default) | ||||

| Support For wobble Shapes | Point,Circle,Line and many other shapes(-、o、◎、◎、^、8) | ||||

| Interface Type | QBH | ||||

| Observation Methods | CCD | ||||

| Cooling Method | Water Cooling | ||||

| Protective Gas | Argon/Nitrogen | ||||

| Max. air pressure(Mpa | 0.6 | ||||

| Electricity Supply(V/Hz) | 380/50 | ||||

| Max.power (KW) | 8 | 11 | 15 | ||

| Robot | Kawasaki (Japan) | ||||

| Arm length | 1.725m | ||||

| Loading weight | 20KG | ||||

| No.Control Axes | 6 | Motor Output(kw) | J1 axis | 2 | |

| MaxLoad Capacity | 20 | J2 axis | 2 | ||

| Max .Reach(mm) | 1725 | J3 axis | 0.675 | ||

| Pos.rep(mm) | +0.04 | J4 axis | 0.2 | ||

| Motion Range(°) | J1 axis | +180 | J5 axis | 0.2 | |

| J2 axis | +155/-105 | J6 axis | 0.2 | ||

| J3 axis | +73/-240 | Weight(kg) | ≈230 | ||

| J4 axis | ±270 | Installation | Ground, hanging | ||

| J5 axis | +145 | Levels of protection | Wrist: lP67 Base axis: lP65 | ||

| J6 axis | +360 | Ambient temperature/Humidity/Vibration | ●Ambient temperature:0~45°C. ●Ambient humidity: usually below 75%RH (no Frost phenomenon)Short-term below 90%RH (within 1 month) ●Vibration acceleration: below 4.9m/s2 (0.5G) | ||

| Max.Speed*(°/s) | J1 axis | 190 | |||

| J2 axis | 205 | ||||

| J3 axis | 210 | ||||

| J4 axis | 400 | ||||

| J5 axis | 360 | Electronic Control Box Specification | Three-phase 380VAC.50Hz/60Hz | ||

| J6 axis | 610 | 580mmx460mmx870mm | |||

| Materials | Reaction | |

| Metal | Stainless steel | √√ |

| Aluminum | √ | |

| Anodized aluminum | √√ | |

| Brass | √ | |

| Nickel alloy | √√ | |

| Copper | √ | |

| Galvanized steel | √ | |

| Gold, silver, nickel, platinum | √√ | |

| Carbon steel | √√ | |

| Titanium | √√ | |

| Gold | √ | |

Excellent Reaction: √√ Good reaction: √ Poor reaction: -

Metal Fabrication

Aerospace

Automotive

Kitchen & Bath

Automatic laser welding machine

Laser welding machine

Handheld laser welding machine

mini laser welding machine

content is empty!