- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-01-06 Origin: Site

Laser welding is a modern welding technique that uses a focused laser beam to create a high-quality weld. It is a fast and efficient method that is increasingly being used in various industries, including automotive, aerospace, and electronics. However, like all welding processes, laser welding has its hazards, and it is important for welders to be aware of these hazards and take appropriate precautions to protect themselves.

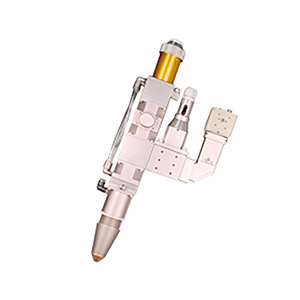

Laser welding is a process that uses a highly focused laser beam to melt and fuse materials together. The laser beam is typically generated by a solid-state laser, such as a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser or a fiber laser. The laser beam is then focused through a lens system to create a small, intense spot on the surface of the workpiece.

Laser welding is a versatile and precise welding technique that can be used to weld a variety of materials, including metals, plastics, and ceramics. It is commonly used in industries such as automotive, aerospace, electronics, and medical devices.

One of the key advantages of laser welding is its ability to produce high-quality welds with minimal distortion and heat-affected zone. This is due to the high energy density of the laser beam, which allows for deep penetration and rapid melting of the material. Laser welding also offers the ability to weld thin materials and small parts, which can be challenging with traditional welding methods.

In addition to its high precision and versatility, laser welding is also a fast and efficient process. The high speed of the laser beam allows for rapid welding, which can increase productivity and reduce manufacturing costs. Laser welding can also be easily automated, making it suitable for high-volume production environments.

When working with laser welding, it is important to take appropriate safety measures to protect yourself from the hazards associated with the process. Here are some key safety measures to consider:

Laser welding produces intense light and laser radiation, which can be harmful to the eyes. It is crucial to wear appropriate laser safety goggles or glasses that are specifically designed to protect against the wavelength of the laser being used. Ensure that the goggles or glasses are in good condition, free from scratches or damage, and properly fitted to your face.

Laser welding can generate high temperatures and molten metal, which can cause burns or skin injuries. Wear appropriate protective clothing, such as flame-resistant coveralls or welding aprons, to shield your skin from heat and sparks. Additionally, consider using gloves that are suitable for laser welding to protect your hands.

Laser welding produces fumes and gases that can be harmful if inhaled. Ensure that the welding area is well-ventilated to allow for proper air circulation. If working indoors, use local exhaust ventilation or fume extraction systems to capture and remove hazardous fumes from the breathing zone.

Maintain a clean and organized workspace to minimize the risk of accidents and injuries. Keep flammable materials away from the welding area and ensure that emergency exits are clear and accessible. Properly store and label any hazardous materials or chemicals used during the welding process.

Ensure that all workers involved in laser welding operations are adequately trained and familiar with the specific hazards associated with the process. Training should cover safe work practices, emergency procedures, and the proper use of personal protective equipment (PPE). Supervision may be necessary, especially for inexperienced workers, to ensure that safety protocols are followed.

Ensure that laser welding machines are properly maintained and equipped with safety features such as interlocks, emergency stop buttons, and protective enclosures. Regularly inspect the equipment for any signs of damage or malfunction, and report any issues to a qualified technician for repair.

Be prepared for emergencies by having appropriate first aid supplies readily available. Ensure that workers know the location of emergency exits, fire extinguishers, and first aid stations. Conduct regular drills to practice emergency evacuation procedures and familiarize workers with emergency response protocols.

Laser welding is a highly efficient and precise method of joining materials, but it also presents various hazards that need to be addressed. By implementing appropriate safety measures, such as using personal protective equipment, ensuring proper ventilation, maintaining a clean workspace, providing training and supervision, ensuring machine safety, and being prepared for emergencies, workers can significantly reduce the risks associated with laser welding. It is essential to prioritize safety and adhere to established protocols to create a safe working environment for laser welding operations.