- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

High-Powered Performance

With options like the 1200W laser welding machine, these devices deliver exceptional power for varied welding requirements, ensuring swift and precise welds.

Compact and Versatile Design

Compact form factor and versatile design allow seamless maneuverability in intricate welding projects, enabling access to challenging areas.

Multi-Functional Capability

The 3-in-1 laser welding machine boasts versatility, combining welding, cutting, and engraving functions in a single device, optimizing workspace efficiency.

Enhanced Precision and Control

Cutting-edge technology ensures pinpoint accuracy and real-time control, guaranteeing impeccable welds across various materials.

Robust and Durable Build

Constructed with high-quality materials, these machines offer longevity and durability, withstanding rigorous industrial use.

User-Friendly Interface

Intuitive controls and user-friendly interfaces simplify operation, reducing training time and ensuring seamless integration into workflows.

Parmeter

Model | NWA02 |

Laser wavelength | 1070nm |

Maximum average power of laser output | 1200W |

Welding head type | Single webble mode |

Fiber length | 10 m |

Weight of Welding torch/gun | 0.8 kg |

Spot adjustment range | 0-5mm |

Focus vertical adjustment range | ±10 mm |

Spot adjustment range (handheld welding mode) | 0~5 mm |

Spot adjustment range (cleaning mode) | F150 0~30mm (F400 0~60mm/F800 0~120mm)Optinal |

Protective lens | D20*2 |

Collimating lens | D20*3.5 F5 |

Focus lens | D20*3.0 F150 |

Function | Welding/Cleaning/Cutting |

Working temperature | 0-45°C |

Working environment humidity | <70% |

Protective gas | Argon/Nitrogen |

Maximum support air pressure | 15 Bar/1.5Mpa |

Electricity | AC220V 50Hz/60HZ |

Maximum power consumption | 5KW |

Dimension | 750*350*600mm Auto feeder:560mm*250mm*350mm |

Weight | 46kg |

Comparison | Air-Cooled Laser Welding Machine | Water-Cooled Welding Machine |

Weight | Lightweight at only 40KG, enhancing portability without compromising performance | Tends to be bulkier and heavier due to complex cooling systems |

Energy Consumption | Energy-efficient, reducing operational costs | Demands more energy for cooling, contributing to higher operational costs |

Simplicity & Convenience | No need for external water sources or complex cooling setups, ensuring hassle-free operation | Requires external water sources and intricate cooling mechanisms, leading to a more complicated setup |

Industrial Manufacturing

Metal laser welding machines cater to the demands of industrial manufacturing, including automotive, aerospace, and machinery industries, ensuring high-quality welds and precision.

Small-Scale Operations

Small laser welding machine prices make them ideal for small businesses, workshops, and artisanal craftsmen seeking professional-grade welding solutions within budget constraints.

Versatile Applications

From metalworking to jewelry making, these devices excel in diverse applications, demonstrating prowess in welding, cutting, and engraving functions.

Application

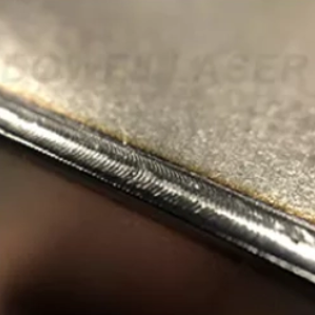

SPOT WELDING

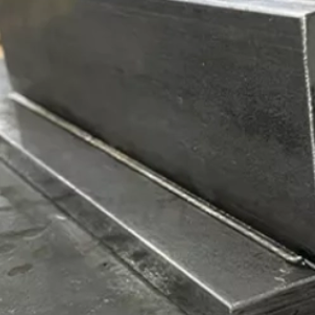

EXTERNAL CORNER WELDING

SHADED CORNER WELDING

DIAGONAL WELDING

SEAL WELDING

CIRCULAR ARC WELDING

content is empty!